Paper tissue packaging machine

Today, in the paper tissue packaging machine industry, it is considered a combined knowledge of science and art that is used to protect and also enclose paper tissues during the distribution, storage and sales processes. In addition, the product packaging industry is also responsible for designing, examining and evaluating different aspects and preparing and producing packaging.

How to package products is a very important step in your marketing and can overshadow the quality of food.

Paper tissue packaging machine is one of the industrial machines that is widely used in packaging various tissues in mass production factories.

Using these devices allows products to be packaged in less time and in larger quantities. In addition, the hygiene of tissues is also increased. Hotels, inns, etc. are among the regular customers of paper tissue production factories.

Boxes designed for tissue paper should be as convenient and useful as the product itself, practical and have an attractive and creative design.

So that it attracts customers. The recyclability of tissue paper boxes is also another factor that is important in their manufacture and preparation. Some tissue paper boxes of famous brands also have a collectible aspect.

Among the raw materials for making tissue paper boxes, cardboard is considered one of the best. Because it is recyclable, and in this case, environmentalists can use these products with more peace of mind.

The process of making and producing paper towels

1. First, the bark of the trees is separated in the relevant factories and turned into thin sheets. So that their outer layer is considered as thin as possible.

2. The layers cut in the previous stage are turned into pieces whose approximate size is estimated to be 1 to 1.4 inches.

3. The cut pieces of wood are cooked with chemicals and combined together, in which stage a mixture is formed that is directed towards pressure ovens at a height of approximately 18 meters called digesters.

4. When the materials are cooked at high temperatures, a large part of the moisture in the wood is lost and ultimately a noticeable weight loss occurs in the weight of the product. The product obtained in this section contains cellulose, lignin and fibers. Of course, the contents of the product are not limited to these and also have other derivatives.

5. In this section, where the pulp is made, it is directed to the washing systems. In this section, lignin (the glue that binds the fibers together) and chemicals that were previously added to it during cooking are removed. After this stage, a liquid called black oil is separated from the pulp and the materials enter the next stage.

6. The washed pulps, which were combined with vegetable bleaching materials, destroy the colors produced from the fibers. Ultimately, a white pulp is formed. In this case, the fiber glue no longer turns the paper yellow over time.

7. At this stage, the pulp is mixed with water again. The pulp loses a lot of water by passing the papers through mesh plates. Eventually, matted sheets are formed, which are about 5.5 meters wide and are produced at a speed of approximately 1981 meters per minute.

8. The matted sheets produced in the previous stage are finally directed into large cylinders.

These cylinders are called Yankee dryers. These sheets are compressed in these cylinders, then dried. At this stage, the final moisture content of the sheets is reported to be about 5%.

9. At this stage, the sheets that have been dried in the previous stage are so-called creped. This means that they become slightly soft and take on a crimped appearance. The papers are scratched by metal blades during the creping process. Of course, this process makes their texture very flexible.

10. At this stage, the papers that have achieved proper flexibility in the pre-flexibility stage are wrapped around cardboard tubes.

This movement causes the cardboard papers to be made in different shapes. After that, they are sent to factories for cutting and packaging by tissue packaging machines.

Tips for buying a tissue packaging machine

The choice of the type of tissue machine depends on the type of use and expectations of the users. Types of wet, pocket, toilet (Delsi), kitchen roll and cloth tissues can be made with the help of various devices such as hand sewing machines, pedal sewing and rail sewing.

Rail sewing machines are considered the most popular type of these machines due to their reasonable cost and the many features they offer to users, as well as their acceptable speed.

Price of tissue packaging machine

There are several factors that affect the price of tissue packaging machines. It is recommended that you consider these things before purchasing this product to make the best choice.

Tissue packaging machines, like other industrial machines on the market, can have different prices depending on the type of model, whether it is original or not, and its design.

These prices can include different costs depending on the type of function and benefits that this machine offers to applicants. In addition, the type of raw materials used in the manufacture of this machine is another important factor that will affect the final price of this product.

We recommend that you ask several sources for the price of the model you are considering before purchasing so that you do not end up paying additional costs.

The cost of the devices, the amount of budget required to purchase the devices, the type of payment method, the types of technologies and technologies used in the manufacture, production and supply of packaging devices, the space available and the cost of setting up their production line are among the factors that will have a great impact on determining the final price of this type of device.

Common problems in using the device:

Tissue packaging devices, like other industrial machines, can have defects and problems in their operation and activity under certain conditions.

In such cases, we recommend that you refer to the relevant agencies before taking any action.

Since the manufacture and production of these devices are carried out under their supervision, they are fully familiar with the structure and type of material used in them.

That is why they can provide the best help in improving your device.

Also, discounts and warranties related to your device may be available.This can be considered a bonus for you in reducing repair costs.

Since tissue packaging machines can have differences in the structure and type of raw materials used in them, it is generally not possible to name their possible problems. However, according to the studies conducted, a few of the most common related problems can be mentioned.

We will examine a few of these cases below.

Among the problems that can be mentioned in tissue packaging machines, there are problems in the actuators or sensors built into these machines. They may turn on correctly, but their operation and functioning may encounter fundamental problems. Occasionally, the packaging process of different types of tissues may be incomplete and with minor problems. It has also been observed that the packaging machine tears the packages.

In some cases, the machine may not turn on at all at first. Of course, these things are not observed in all tissue packaging machines and vary depending on the type of machine and its function.

We recommend that if you see any symptoms in your machine, refer to the relevant repair centers. Consulting with uninformed people can easily overshadow the operation and activity of your machine and multiply the problems of the machine.

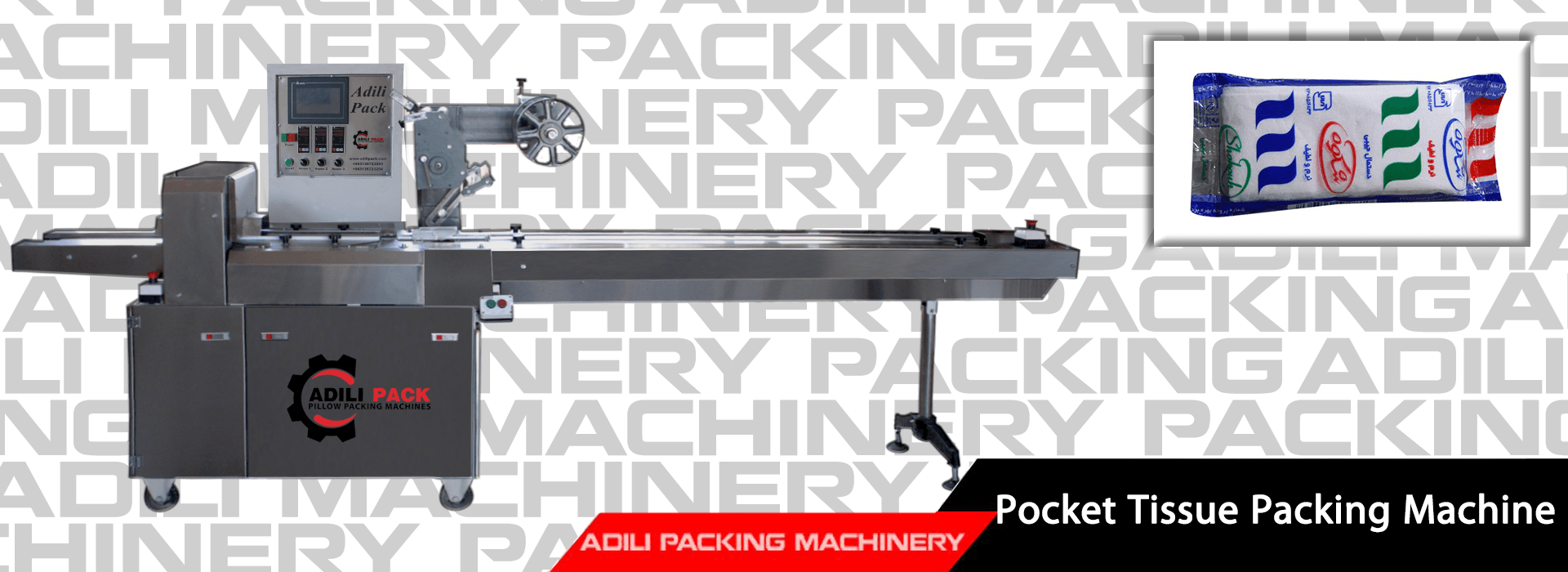

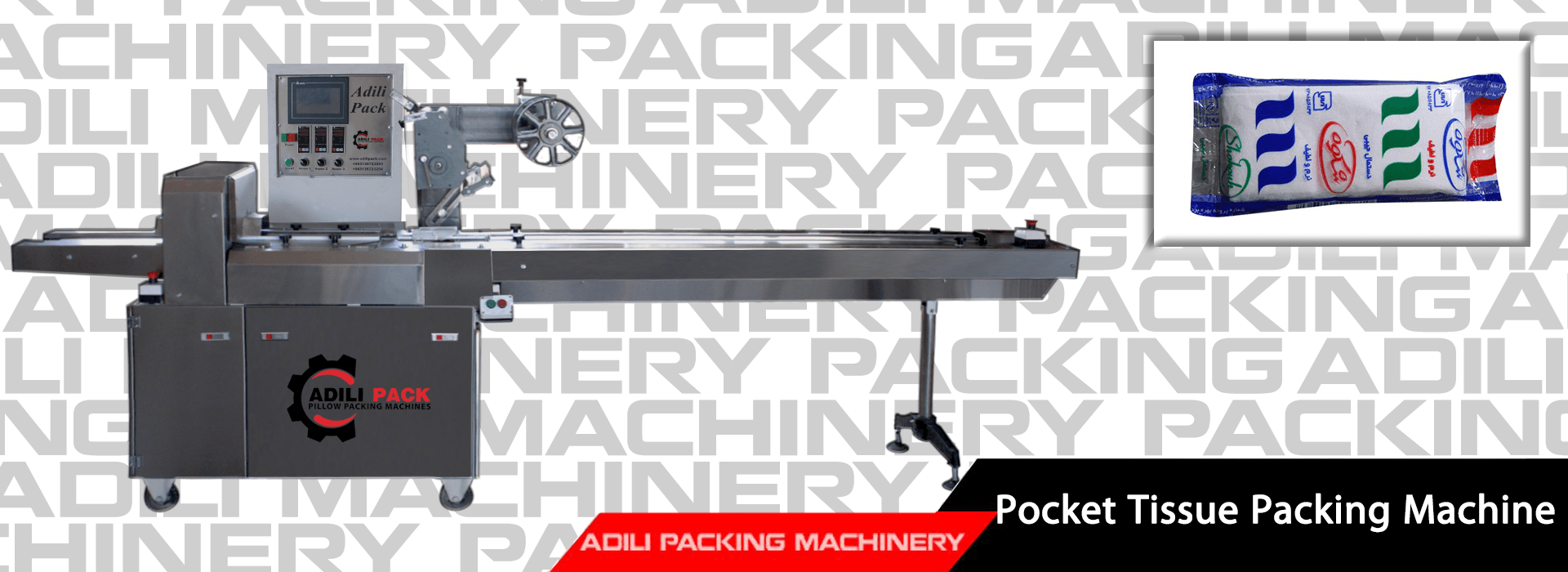

Pocket Tissue Packaging Machine

Pocket Tissue Packaging Machine is an example of a packaging machine with a PLC system, mechanics with a photocell eye and simple mechanics that packages products in a pillopack (two-sided stitching). This machine is used to package products such as paper towels, soap, disposable tablecloths, gloves, garbage bags, diapers, scotch tape, dishwashing detergent, etc.

Unique advantages of Pocket Tissue Packaging Machine Pilupek Machine Sazi Adili:

- Protection of food products against light, moisture and dust and preventing their spoilage.

- Ability to package products in various dimensions at high speed and without waste.

- Has a protective sensor that cuts off the power of the machine if a hand touches the jaw gate.

- To prevent rust and decay of the machine, which is sometimes exposed to water and sun, all parts used are made of steel.

- Ability to work with thermal and adhesive cellophane (cold seal and hot seal).

- Ability to adjust the speed of the machine (number of packages per minute).

Packaging machines Horizontal Pilopacks are very similar in terms of appearance and technical specifications, and their main differences are in packaging dimensions, packaging speed, PLC and mechanical systems, and the presence of a photocell eye for printed cellophane.

Technical specifications of the device

Device length: 4 meters

Machine width: 1 meter

Machine height: 1.7 meters

Power consumption: 3 kW

Packing speed: 100 packs per minute

Machine weight: 450 kg

Information required by the device

This machine is suitable for packaging medium-sized products (8 to 20 cm wide) and is offered in the form of Pilopack (two-sided stitching), using hot seal and cold seal technology (related to packaging speed), as well as other peripheral features of the machine according to customer needs.

For more information, contact our experienced consultants and sales experts:

0913119203503135721565031357232930313572329403135723295

Concluding Remarks

As mentioned in the text, today industrial machines have been able to occupy a large part of the market. Tissue packaging machines that are responsible for packaging various types of tissues are among these machines.

This method can be done completely automatically and without manual intervention. This is one of its advantages. Because the environment is sterile and sanitary rules are fully implemented in it. That is why this machine has found many fans in the packaging industry market.

xxxxxxxxxx