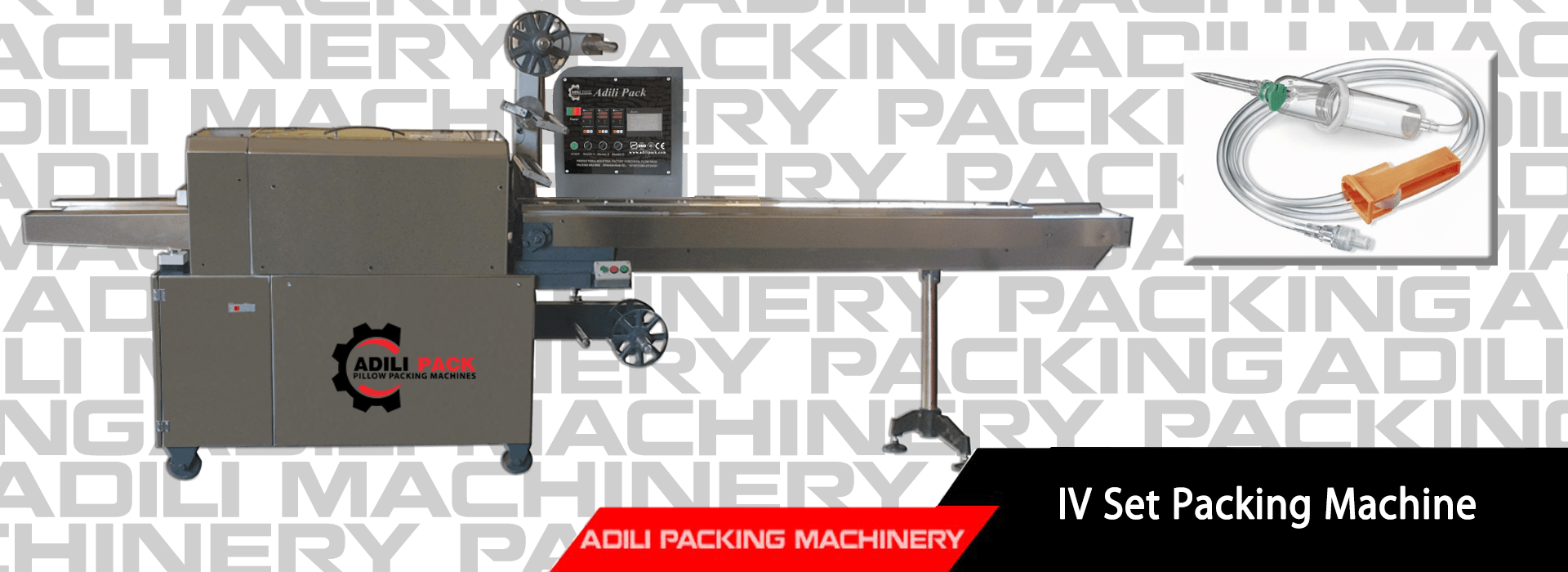

Serum set packaging machine

In this article, we intend to provide you with useful and valuable information about Serum set packaging machine.

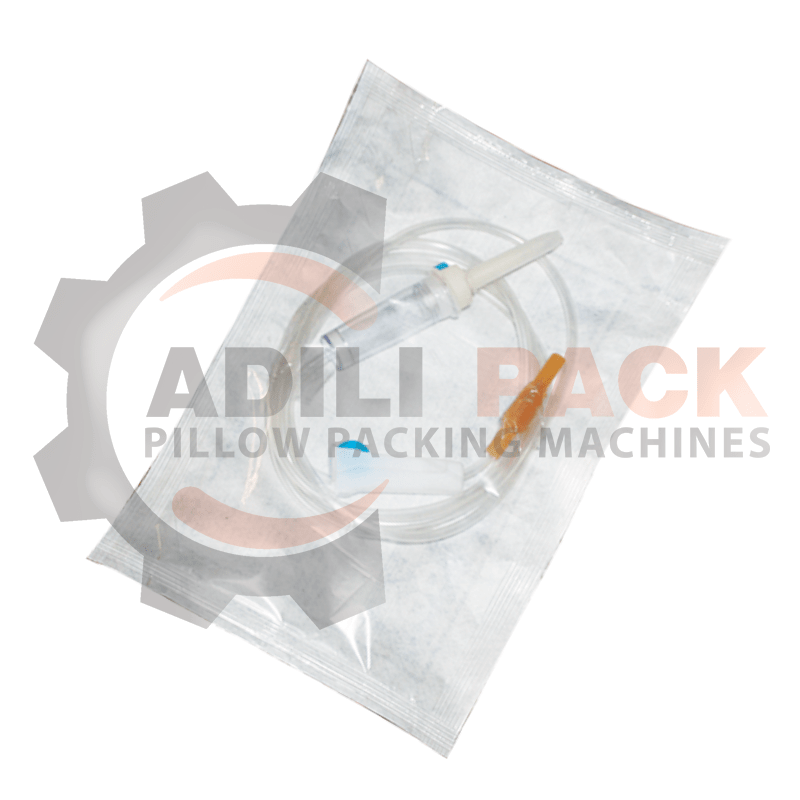

The serum set machine is the interface between the serum and the patient’s body and is disposable, meaning it must be sterilized after each use. As a result, sterilizing it after packaging is very necessary.

Because it will be a game with the lives of patients. If you are looking to purchase a pillopack machine for packaging serum sets, our suggestion is a model of the highest quality and highest quality of this model, while the standardization of this machine is of great importance.

You definitely need to order this machine from the sample, sewing on all four sides. Because if you use the sample with two sewing sides of the pillopack machine, the final packages will not be able to be sterilized and you will face many problems when entering the product into the market.

In addition, it is also dangerous for patients. But in the fourth sample, the sewing side is able to sterilize the packages because 2 types of roll materials can be used. If the serum sets are not sterilized before entering the market, it is contrary to the rules of the Food and Drug Administration, and it should be noted that it will not be standard either, and you will definitely not be able to obtain the necessary permits to enter the market.

Features of the serum set packaging machine

Among the features of this model of packaging machine are the following.

The ability to package products in different sizes and at high speed and without waste, which is also very cost-effective.

It has a protective sensor that cuts off the power to the machine if the hand touches the jaw gate. This feature prevents fatal accidents.

To prevent rust and decay of the machine, which may be exposed to water and sunlight, all parts used are made of genuine steel.

The ability to adjust the machine’s high speed to a high number of packages per minute.

Four-side stitching packaging machines are very similar in terms of appearance and technical specifications, and their main differences are in the packaging dimensions, packaging speed and mechanical system, as well as having a photocell eye for printed cellophane.

Four-side stitching machines are very suitable for serum sets and are usually used to package serum sets.

Its most important feature is that its waste is close to zero.

The speed of the machine can be adjusted by an inverter, which can adjust the number of packages required per minute.

Depending on the customer’s needs, this machine can be adjusted and its number.

Also, this machine is fully automatic and without manual intervention, it is tactile and is very important for precise adjustment and control of the machine’s performance.

This machine is equipped with an eye for accurate detection of the cutting, sewing and packaging location.

The machine is equipped with an operator’s hand detection sensor to cut off the machine’s power to prevent danger in the sewing jaw section of the machine for the operator or the person in charge of the machine.

The machine is made entirely of high-quality stainless steel that does not rust or corrode and is fully compliant with the Food and Drug Administration to obtain the necessary permits for the entry of health and hospital products into the market.

It is used for packaging medical equipment such as catheters, insulin syringes, surgical equipment, dental equipment, etc.

Components of the Serum Set Packaging Machine

This machine is an example of a packaging machine with a PLC system, mechanics with a photocell eye, and simple mechanics that packages sterile gauze in a four-sided sewing manner. This machine is used to package products such as serum sets, catheters, insulin syringes, angiocatheters, guns and so on.

Unique advantages of Serum Set Machine:

- Ability to package products in different sizes, at high speed and without waste.

- It has a protective sensor that cuts off the power of the machine if a hand touches the jaw gate.

- To prevent rust and decay of the machine, which is sometimes exposed to water and sun, all parts used are made of steel.

- Ability to work with thermal and adhesive cellophane (cold seal and hot seal).

- Ability to adjust the speed of the machine (number of packages per minute).

Technical specifications of the device

Length of the machine: 4.1 meters

Width of the machine: 1 meter

Height of the machine: 1.7 meters

Power consumption: 4.5 kW

Packing speed : 150 packs per minute

Machine weight : 700 kg

Information required by the device

This machine is suitable for packaging medium-sized products (width 10 to 17 cm) that are sewn on all four sides, as well as other additional features of the machine according to customer needs.

For more information, contact our experienced consultants and sales experts:

09131192035

031-35721565

031-35723293

031-35723294

031-35723295

xxxxxxxxxx