Medical devices and equipment:

Medical equipment packaging machine is one of the most distinguished devices of this collection, which is produced and provided to our dear customers based on the rules and standards of the world.

Our beloved country, Iran, ranks fourth in terms of engineering in the world, and has more than 1,000 manufacturers of medical equipment and almost 2,000 different types of equipment and hardware facilities for diagnosing, monitoring and treating patients, such as disposable devices. It manufactures from sterile to laboratory and hospital devices, etc., which comply with all safety and performance principles according to European Union standards, and have a manufacturing license from the Ministry of Health of Iran.

After the production of these medical supplies and products, it comes to the important stage of packaging, which is one of the most sensitive stages of the medical equipment production line, because if the packaging is not suitable in any way, both in terms of people’s health and in terms of sales in the market. is faced with a problem.

With the help of God Almighty and the use of capable designers and specialists, Adili Machinery Group has been able to take a big step in the development of this industry by producing standard and diverse packaging machines. The packaging devices of this collection have many uses, including things like packing: sterile gas, serum sets, bandages, syringes, guns, applicators, angiokets, catheters, and producing and packing masks.

Types of medical equipment packaging devices in this field:

One of the types of packaging devices for Adili medical supplies, device Sterile gas packaging, with the best quality in the type of packaging and the least error, with easy design and operation, is able to package this product in four-sided stitching, which is used to package this product against the protection of Environmental factors and pollution can be used with the AMP900 model device.

The other packaging machine is related to the types of bands, which are equipped with PLC system, mechanical with photocell eye and simple mechanical, and it packs the products in the form of pillopack (sewing on both sides).

This device is used for packing products similar to bandages, tapes, rolls of bandages, etc.

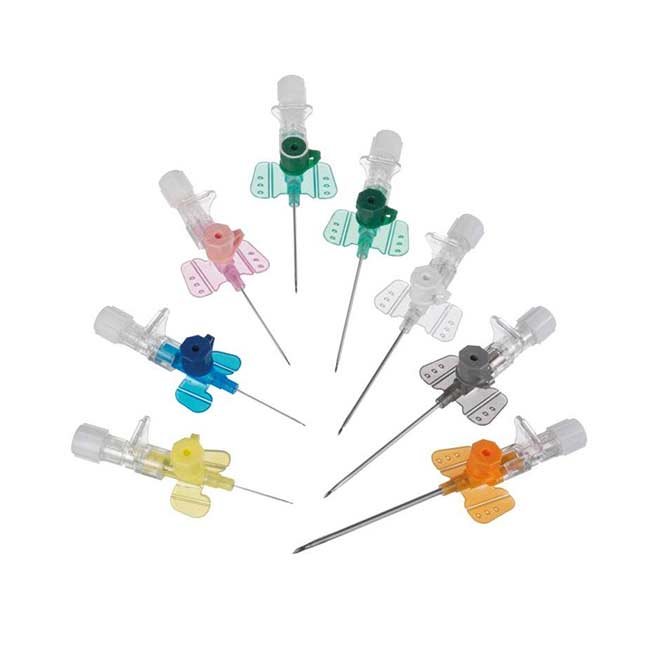

The other device is the syringe packaging device, which is used for products similar to serum sets, catheters, insulin syringes, angiokets, guns, etc.

And the last medical equipment packaging machine that we mention from this series is the three-layer medical mask production and packaging machine with ultrasonic sewing system and three layers of special fabric for the mask, which gives more details on the three-layer medical mask production machine. has been, is

Manufacturing medical equipment packaging machine:

Due to human progress in medical science, the human need for new medical equipment has increased and as a result, the production of medical products has increased, which leads to the increasing competition of machinery industries in the production and provision of medical equipment packaging devices.

Among these competitions, it can be said that Iran is one of the countries that has a lot to say in this industry, that Adili machine factory is one of the most proud machine building complexes in Iran.

In this regard, good design and high quality will be very effective in this competition. In the device manufacturing stage, it should be ensured that all the desired factors in the design and manufacturing of medical equipment packaging devices are implemented correctly.

Advantages of equipment packaging machine

The four-sided stitching and horizontal pillopack packaging machines are all very similar in terms of appearance and technical specifications, and their main difference is in the packaging dimensions, packaging speed, and its PLC and mechanical system, as well as having a photocell eye.

The unique advantages of the device:

- Ability to pack products in different sizes and at high speed without waste

- It has a protection sensor that cuts off the power of the device if the hand touches the jaw gate.

- To prevent the device from rusting and rotting, which is sometimes exposed to water and sunlight, all the parts used are made of steel.

- Ability to work with thermal and adhesive cellophanes (cold seal and hot seal)

- The ability to adjust the speed of the device (number of packages per minute)