Mask Packaging Machine

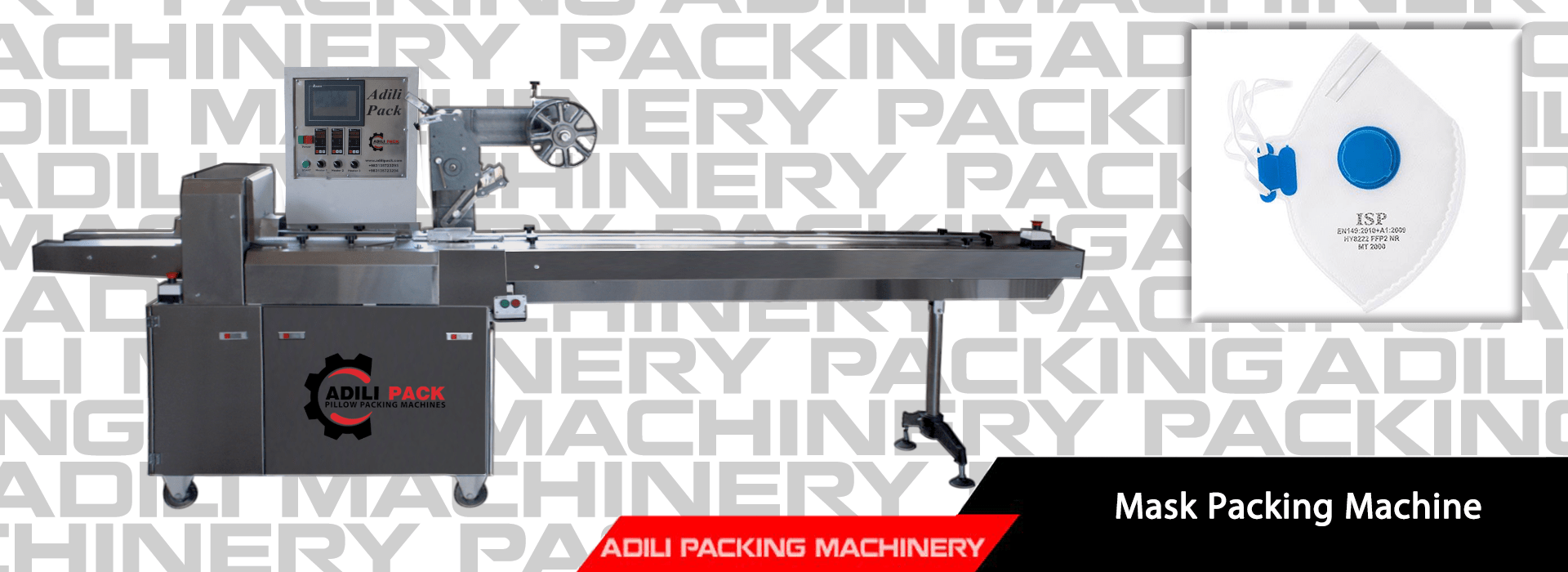

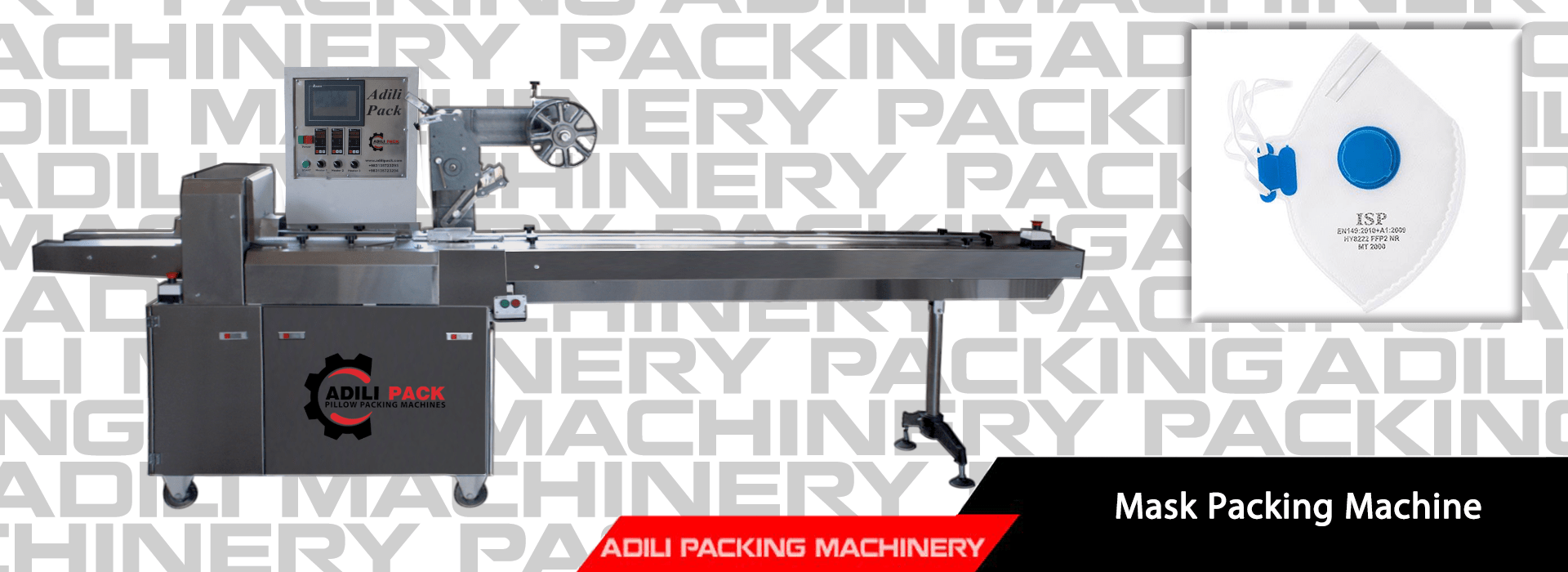

Mask Packaging Machine is an example of a packaging machine with a PLC system, mechanics with a photocell eye and simple mechanics that packages products in a pillopack (two-sided stitching). This machine is suitable for packaging all types of medical masks, including three-layer masks and filtered masks.

Unique advantages of Pilopack mask packaging machineAdili Machinery:

- Ability to package products in different sizes, at high speed and without waste.

- It has a protective sensor that cuts off the power of the machine if a hand touches the jaw gate.

- To prevent rust and decay of the machine, which is sometimes exposed to water and sun, all parts used are made of steel.

- Ability to work with thermal and adhesive cellophane (cold seal and hot seal).

- Ability to adjust the speed of the machine (number of packages per minute).

Horizontal Pilopack packaging machines are very similar in terms of appearance and technical specifications, and the main differences are Their differences are in packaging dimensions, packaging speed, PLC and mechanical systems, as well as having a photocell eye for printed cellophane.

Support and after-sales service of the device:

All packaging devices in this complex have warranty and after-sales service. Providing after-sales service of the Adili Machinery Complex is a daily response to your questions, dear customers.

It is worth noting that the Adili Machinery Factory Service Unit will first try to solve the problem of the device by phone, and if the problem is not solved, we will send our experienced engineers to you inside and outside the borders and provide the best possible service for the device failure.

Technical specifications of the device

Device length: 4 meters

Machine width: 1 meter

Machine height: 1.7 meters

Power consumption: 4 kW

Packing speed: 100 to 200 packs per minute

Machine weight: 500 kg

Required device information

This machine is suitable for packaging medium-sized products (8 to 20 cm wide) and is offered in the form of Pilopack (two-sided stitching), using hot seal and cold seal technology (related to packaging speed), as well as other peripheral features of the machine according to customer needs.

For more information, contact our experienced consultants and sales experts:

09131192035

03135721565

03135723293

03135723294

03135723295