Glove packaging machine video

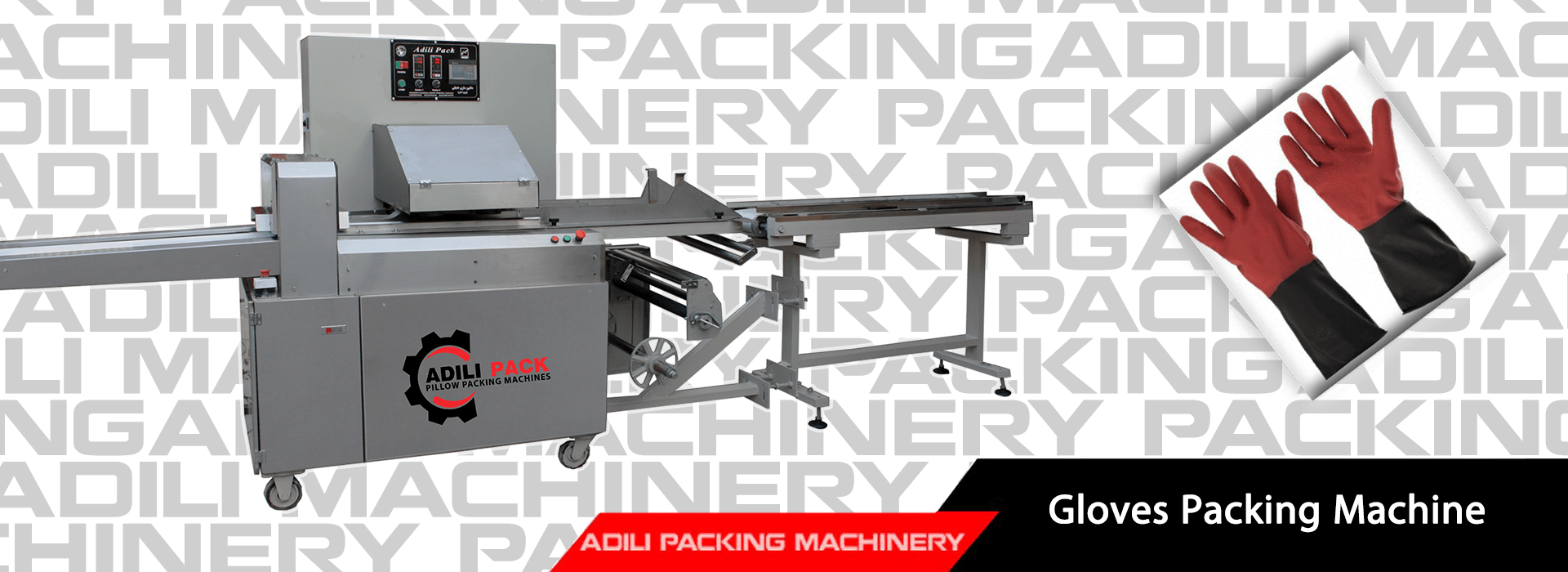

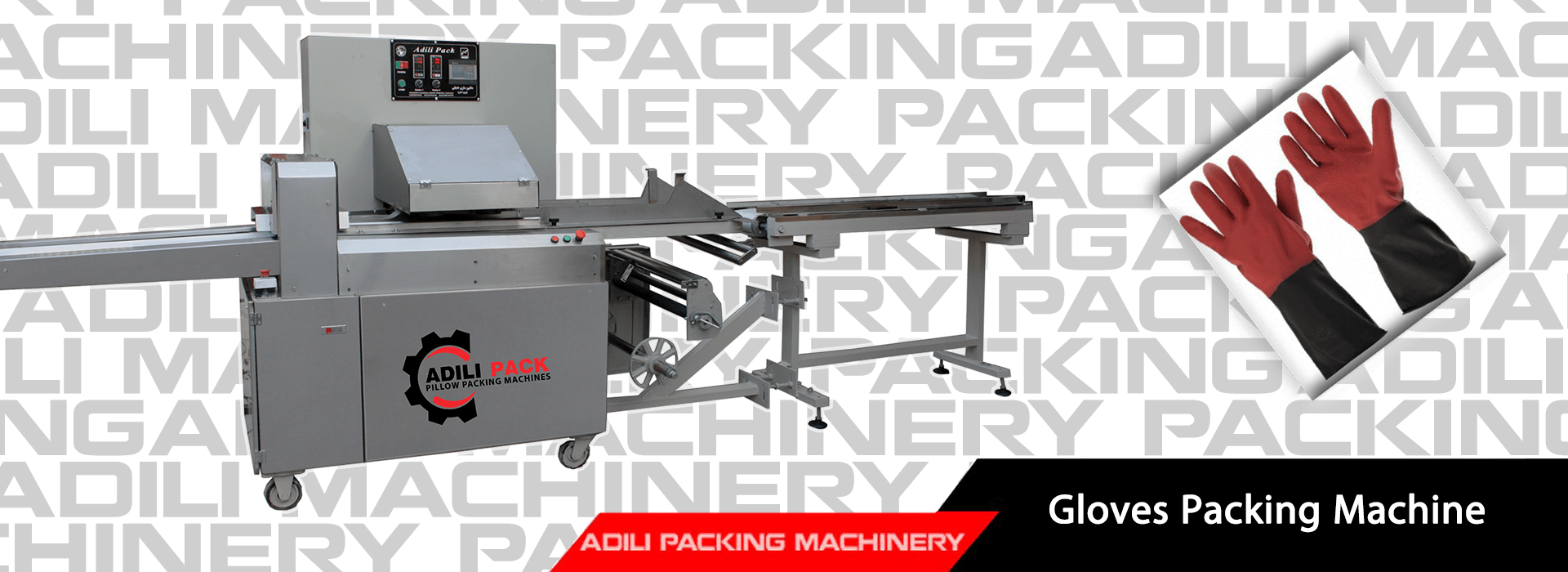

Glove Packaging Machine

Glove Packaging Machine is an example of a packaging machine with a PLC system, mechanics with a photocell eye and simple mechanics that packages products in a pillopack (two-sided stitching). This machine is used to pack products such as tissue paper, soap, disposable tablecloths, gloves, garbage bags, diapers, tape, and dishwashing wire, etc.

Unique advantages of Pilopack Glove Packaging Machine Adili Machinery:

- Protection of food products against light, moisture, and dust and preventing their spoilage.

- Ability to pack products in various sizes at high speed and without waste.

- Has a protective sensor that cuts off the power to the machine if a hand touches the jaw gate.

- To prevent rust and decay of the machine, which is sometimes exposed to water and sun, all parts used are made of steel.

- Ability to work with thermal and adhesive cellophane (cold seal and Hot Seal).

- The ability to adjust the speed of the device (number of packages per minute).

Horizontal Pillopack packaging machines are very similar in terms of appearance and technical specifications, and their main differences are in the packaging dimensions, packaging speed, PLC and mechanical systems, and also having a photocell eye for printed cellophane.

This device is also offered with top-stitching technology according to customer needs.

Technical specifications of the device

Device length: 4 meters

Machine width: 1 meter

Machine height: 1.7 meters

Power consumption: 3 kW

Packing speed: 100 packs per minute

Machine weight: 450 kg

Required device information

This machine is suitable for packaging medium-sized products (8 to 20 cm wide) and is offered in the form of Pilopack (two-sided stitching), using hot seal and cold seal technology (related to packaging speed), as well as other peripheral features of the machine according to customer needs.

For more information, contact our experienced consultants and sales experts:

0913119203503135721565031357232930313572329403135723295