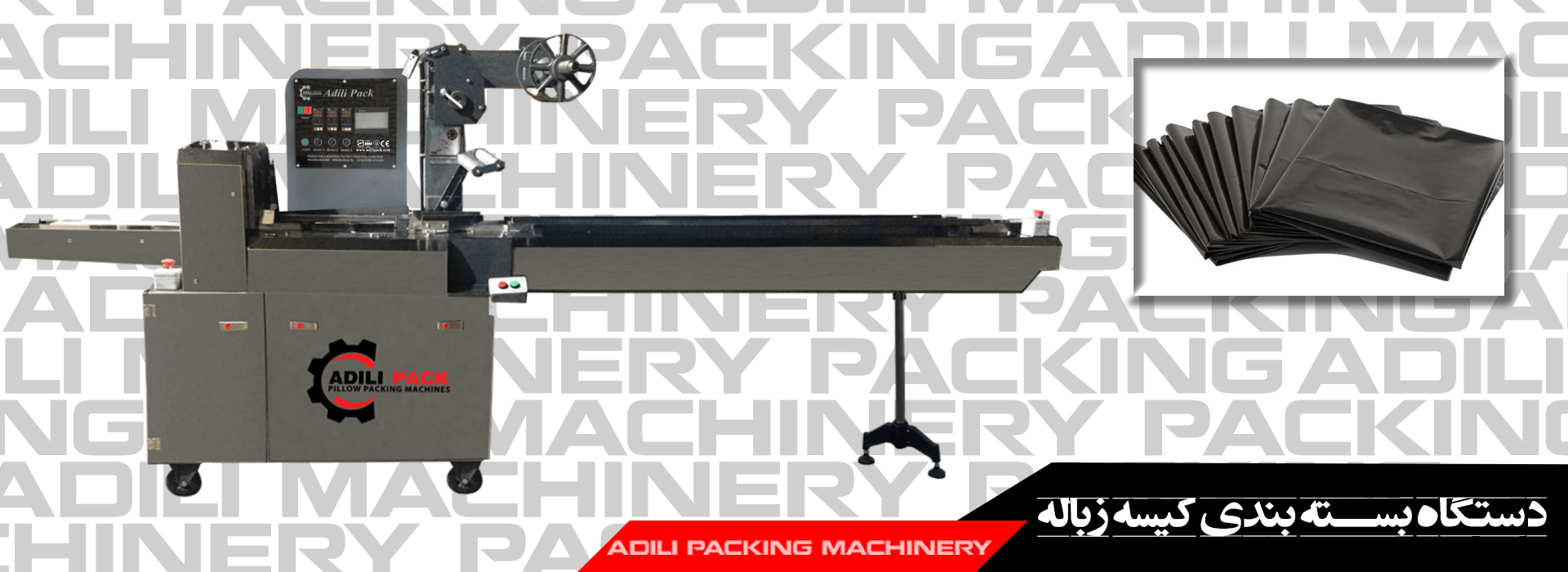

Garbage bag packaging machine

Garbage bag packaging machine is designed and manufactured as a horizontal pillopack and is available in different types and prices on the market today. The parts of this machine are very well equipped and advanced.

The packaging speed of this machine is between 120 and 160 products per minute and can be changed and adjusted according to the customer’s needs. If a person has many customers and has a high daily demand, he can adjust this machine according to the customer’s orders and produce more garbage bags.

This machine is also equipped with a memory to store the sizes of different products. This is one of the special advantages of all packaging machines in the packaging industry that buyers usually pay special attention to.

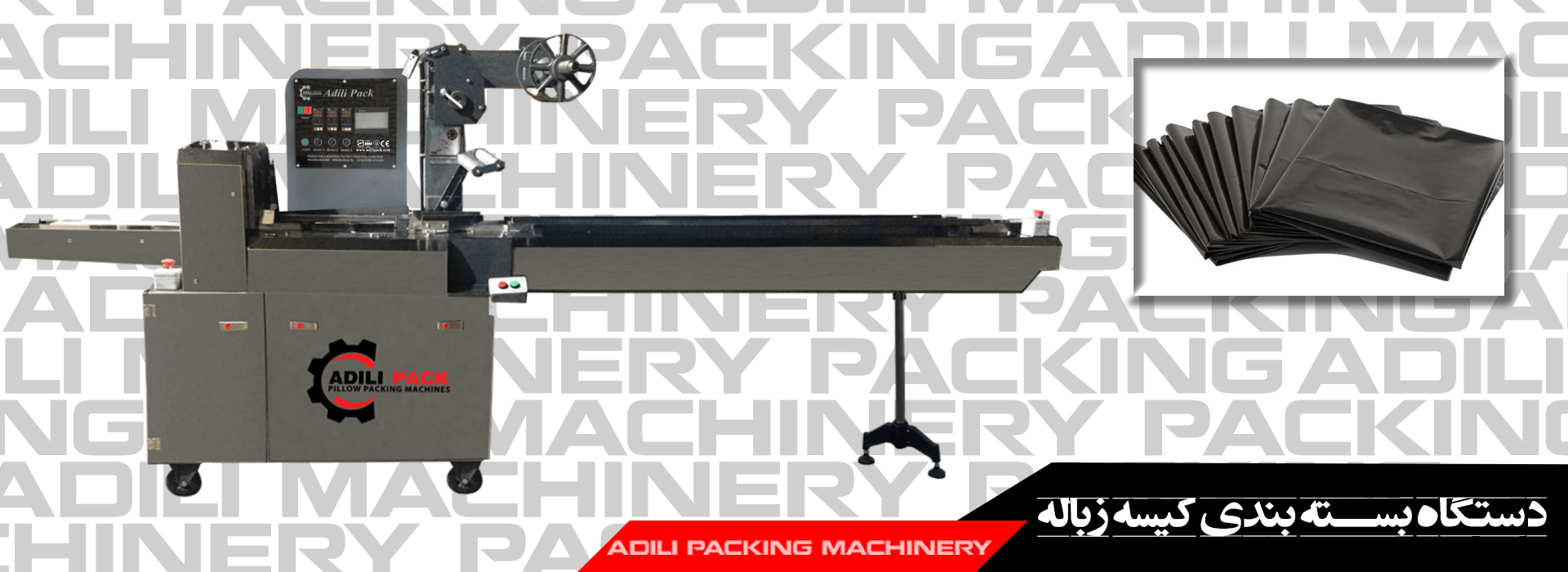

Small or large, thick or thin nylons can be adjusted depending on the customer’s needs.

Note that the garbage bag packaging machine can be used in industrial and semi-industrial environments and works with an input voltage of 220 volts.

In fact, it is compatible with any environment and easily produces all kinds of bags. Another special and special feature of this machine is the presence of a counter system to count and check each work shift.

For this reason, many problems can be solved with this machine. This machine has a very sensitive protective sensor that cuts off the power to the machine as soon as the hand touches the jaw gate.

One of the important and special features of this machine is having accurate sensors. And other things that make using this machine economical for manufacturers.

This machine is an example of a packaging machine with a PLC system, mechanics with a photocell eye and simple mechanics that packages products in a pillopack (two-sided sewing). It is also used to package products such as paper towels, soap, disposable tablecloths, gloves, garbage bags, diapers, scotch tape, and dishwashing detergent, etc.

Features of packaging machines

The existence of packaging machines is of great importance today. Protecting food products from light, moisture, and dust and preventing their spoilage plays an effective role in packaging.

The ability to package products in different sizes, at high speed, and without waste. It has a protective sensor that cuts off the power to the machine if a hand touches the jaw gate.

This reduces or eliminates almost all accidents when working with this machine.

To prevent rust and decay of the machine, which may be exposed to water and sunlight, all parts used are made of genuine steel.

Ability to work with thermal and adhesive cellophane

The ability to adjust the speed of the machine and the number of packages per minute. Horizontal Pilopack packaging machines are very similar in terms of appearance and technical specifications, and their main difference is in the packaging dimensions, its automatic and mechanical packaging speed, and also having a photocell eye for printed cellophane. Garbage bag packaging machines take up little space and for this reason they can be used anywhere.

Garbage bag production steps

In the rest of this article, we would like to explain the steps of garbage bags using advanced and modern machines. To produce garbage bags from raw materials or primary materials, you need to use polymer materials, which are abundantly produced in the petrochemical industry in the country.

The polymer used in the manufacture of garbage bags is polyethylene, which, depending on the type, thickness and multi-layeredness of the garbage bag, is used in light, heavy and linear types. The important point about the bag is that standard and hygienic materials are used. In addition, the raw materials of this type of bag are of high quality. The garbage bag packaging machine in our collection is one of the devices that is no less than foreign models in terms of quality of parts and equipment and is made in different models. To buy a device with the least noise pollution, just buy this device from our capable and professional collection. All the machines supplied by this center have valid after-sales service and warranty and are economically affordable. In addition, you can buy these machines in two ways: online and in person.

Unique advantages of the garbage bag packaging machine:

- Protection of food products against light, moisture and dust and preventing their spoilage.

- Ability to package products in different dimensions at high speed and without waste.

- Has a protective sensor that cuts off the power of the machine if a hand touches the jaw gate.

- To prevent rust and decay of the machine, which is sometimes exposed to water and sun, all parts used are made of steel.

- Ability to work with thermal and adhesive cellophane (cold seal and hot seal).

- Ability to adjust the speed of the machine (number of packages per minute) ) .

Horizontal Pilopack packaging machines are very similar in terms of appearance and technical specifications, and their main differences are in packaging dimensions, packaging speed, PLC and mechanical systems, and the presence of a photocell eye for printed cellophane.

Technical specifications of the device

Device length: 4 meters

Device Width: 1 meter

Height Machine: 1.7 meters

Power consumption: 3 kW

Packing speed: 100 packs per minute

Machine weight: 450 kg

Information required by the device

This machine is suitable for packaging medium-sized products (8 to 20 cm wide) and is offered in the form of Pilopack (two-sided stitching), using hot seal and cold seal technology (related to packaging speed), as well as other peripheral features of the machine according to customer needs.

Contact us for more information.

Sales phone: 031-35721565

xxxxxxxxxx