Another device in the Adili Machinery Group is the Sweet and Chocolate Packaging Machine, which is provided to manufacturers with the highest possible quality.

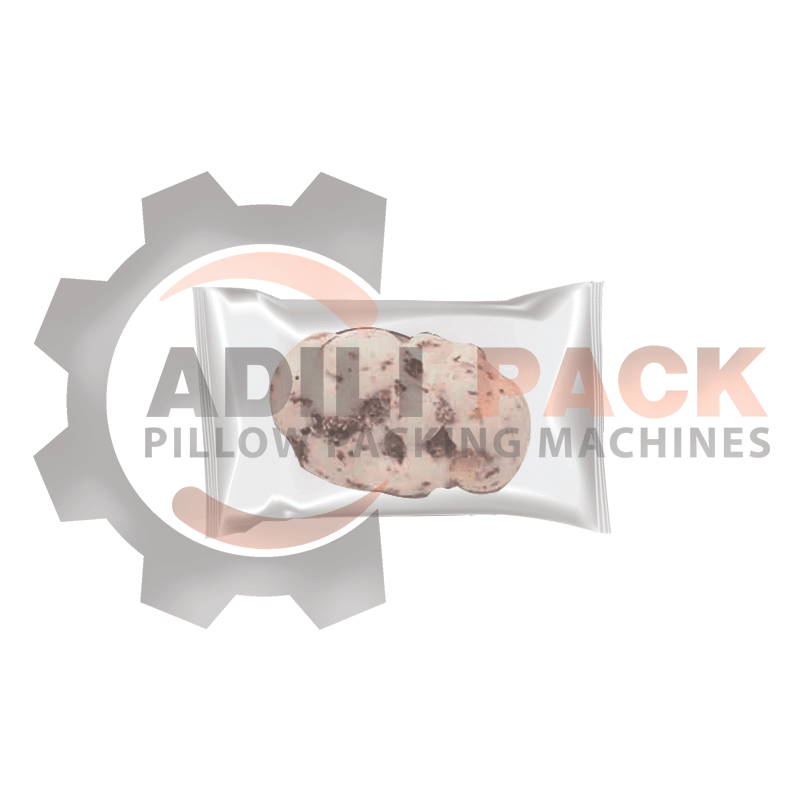

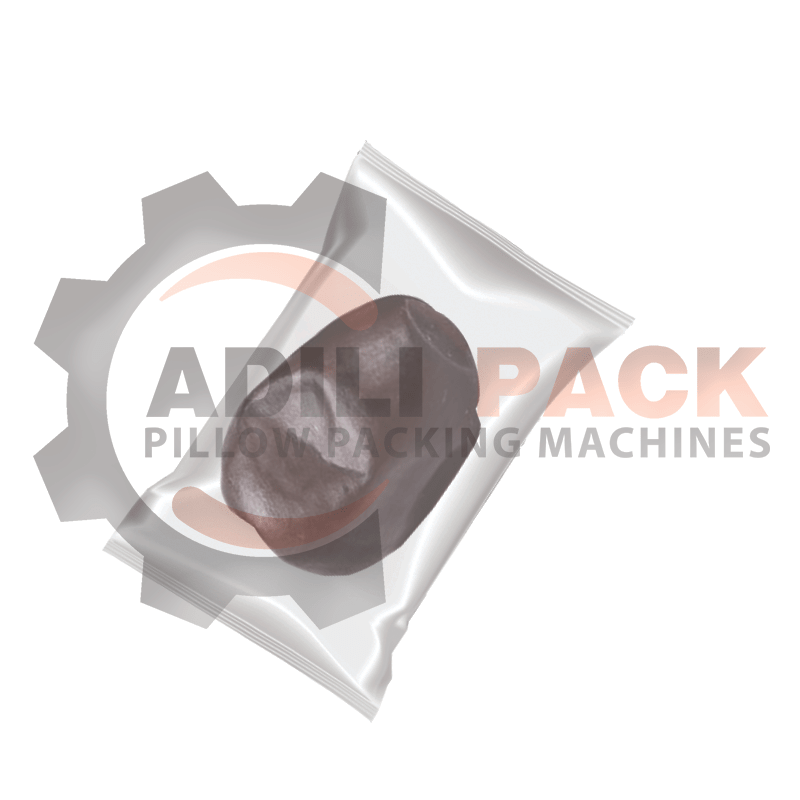

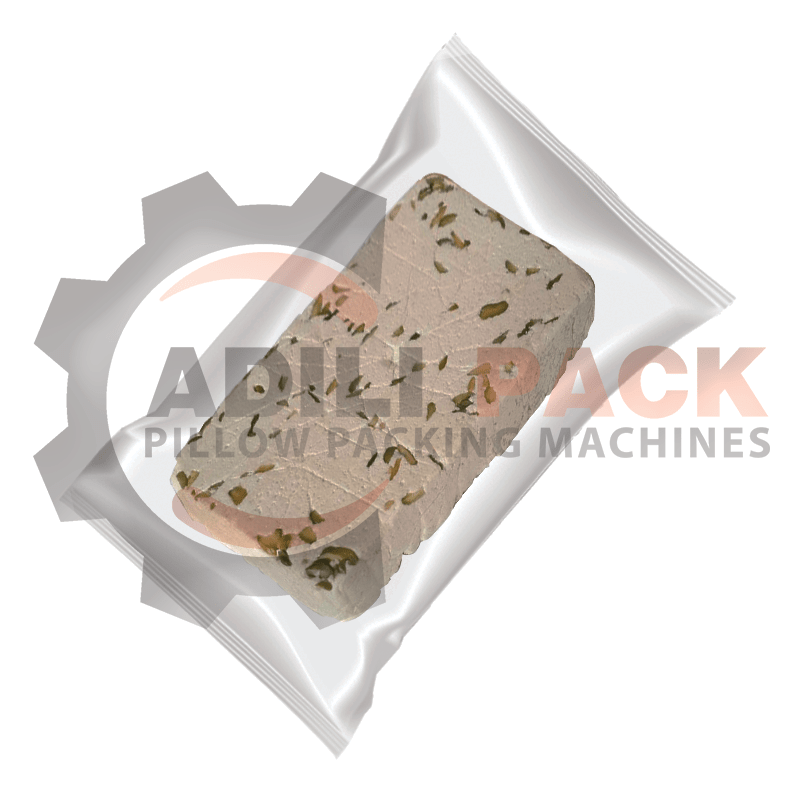

This machine is capable of packaging all kinds of sweets, including: Gaz, chocolate, candied fruit, sugar halva, sesame halva, sohan, dates, nakhl, muskati, sugar rolls, sugar cubes, candies and other products in different sizes, in single and multiple pieces.

Packaging is an important stage in the storage process of a product, especially the packaging of food and edibles, which will be more sensitive in this case.

One of the most important points that should be paid great attention to is observing the hygiene and standards required by the machine.

The importance of beautiful and elegant packaging

The Adili Machine Group’s confectionery packaging machine is suitable for packaging all kinds of sweets with a new and easy method, which can be easily used in factories and also at the workshop level.

In designing confectionery and chocolate packages, it is important that the design is in a way that, as soon as the buyer sees it, he understands the deliciousness of the sweets and the contents of the package and attracts the customer.

Also, the cellophane material has a great impact on the type of sewing of the product, which must be taken into account.

Making a suitable packaging machine for sweets and chocolates

Paying attention to the importance of packaging and the various uses of this product has led to the creation of packaging machine suitable for all kinds of sweets and chocolates.

Considering the competition in the machine industry, Adili Industrial Group, with its brilliant history and experience, has been able to achieve success in this industry by manufacturing various types of packaging machines in various fields.

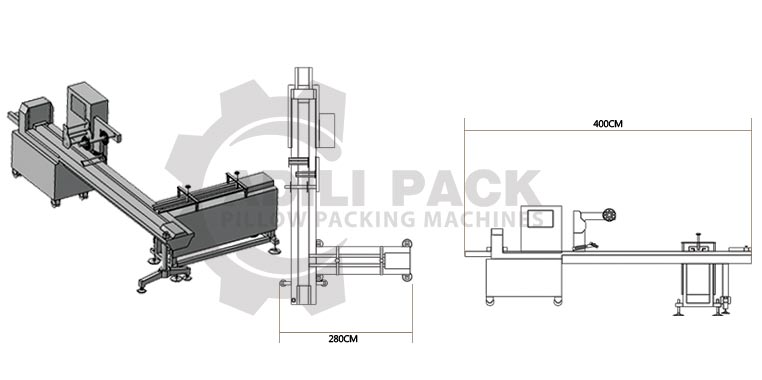

With the AMP810, AMP820, AMP830 models, it is possible to package various types of sweets and chocolates such as: Gaz, Sohan, chocolate, candied fruit, Muscat, chewing gum, dates, etc.

These machines have a similar appearance, but they differ in the PLC system, packaging speed and packaging dimensions.

A feeder can also be used to more easily arrange the product on the Pilupak machine rail.